Ferrotungsten

Home > Ferrotungsten

What is Ferrotungsten?

Ferrotungsten is a ferroalloy that contains iron and tungsten as its main components. It's produced by smelting tungsten ores and iron elements in an electric arc furnace. Ferrotungsten is primarily used as an additive in the production of steel. This alloy helps improve steel's hardness and strength, especially at high temperatures. It is also used in the production of other alloys and in various industrial applications.

Ferrotungsten is of significant global importance and demand across the world. Tungsten is deemed a critical mineral to economies including the USA, UK, EU, Japan, Korea, Russia and Australia.

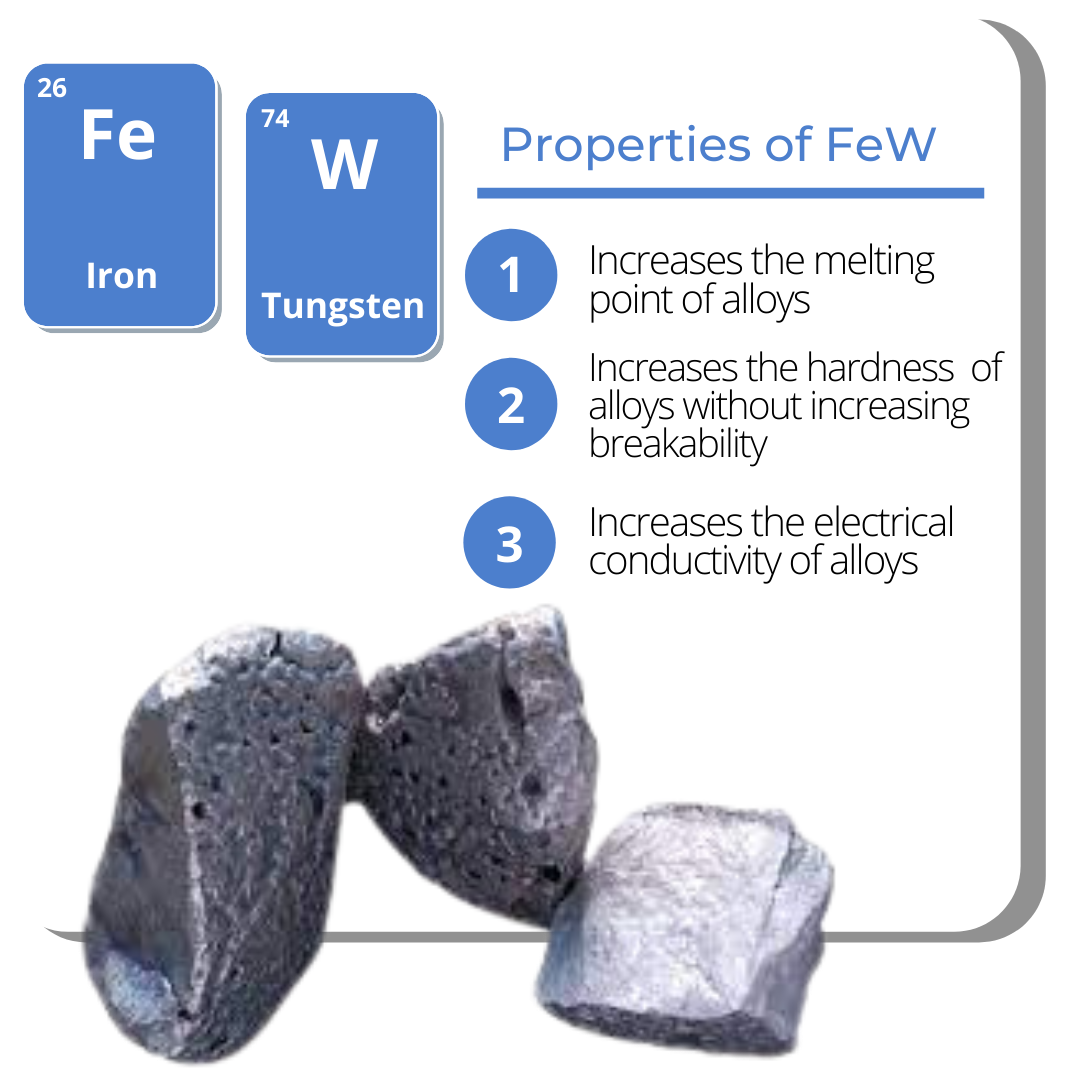

Properties of Ferrotungsten

Ferrotungsten (FeW) is known as a “master alloy”. It typically contains over 75% Tungsten (W), with the remainder being Iron (Fe).

Ferrotungsten has a metallic steel grey lustre and a very high density (14 – 15.5 g/cm3) . It has a very high melting temperature (~2800 deg C) and a fine-grained structure of Fe₂W and Fe₇W₆.

Ferrotungsten Production

Early tungsten alloyed steels were manufactured by adding pure tungsten powder to molten steel. They were also made by adding an iron-rich prealloy, obtained from purified tungsten ore. This expensive procedure limited the application of tungsten steels because of the high price. In 1893, a new 80% tungsten-rich prealloy, was introduced by Biermann ́sche Metallindustrie in Germany. This new alloy was labeled 'ferrotungsten'. Production of ferrotungsten direct from tungsten ores then became possible in an electric arc furnace. This allowed for a much cheaper production process than earlier methods.

Electric Arc Furnace

Using an Electric Arc Furnace has advantages over other methods. These include controlled melting temperatures, faster steel melt dissolution and higher yields.

Our State of the Art Furnace

Tungsten Metals Group utilises a modern Electric Arc Furnace at our Vietnam facility. This method of ferrotungsten production generates a higher quality product than aluminothermic methods.

1

Tungsten concentrate

The most commonly traded form of tungsten is tungsten concentrate.

Wolframite and scheelite are typical tungsten mineral concentrates. These ores contain 60-70% tungsten trioxide (WO₃).

Tungsten concentrate is sourced directly from miners and commodity traders.

Combining tungsten concentrate (≈65% WO₃), pitch coke, ferrosilicon and scrap iron, this forms the ingredients to produce ferrotungsten.

Ferrotungsten Production Process

2

Electric Arc Furnace

Typically, a 2,200kW electric arc furnace is heated to temperatures >3,000ºC.

The concentrates are melted and reduced with two layers (slag & alloy) being produced

The slag layer contains most of the impurities. The slag is removed by tilting the furnace and collecting the slag into slag pots

Further refining occurs with the final ferrotungsten alloy being removed by “digging”.

3

Extraction of Ferrotungsten

Extraction machines are operated by experienced personnel to extract the ferrotungsten

The product is a ferrotungsten master alloy of a nominal 78% tungsten content.

Our Ferrotungsten Factory

World-class ferrotungsten factory based in Vietnam

Largest & most advanced ferrotungsten furnace outside of Russia and China

16 tonnes per day & 4,000 tonnes per annum at current production capacity

21,500sqm land parcel

7 Major facility buildings

Latest generation of ferrotungsten factory design

High voltage power connected to grid

50km from nearby deep sea port

Located 80km SE of Hanoi, and 25km S from Haiphong in the Vĩnh Bảo district

Our Ferrotungsten factory utilises the most advanced technology to efficiently produce high-quality products. Production meets local environmental requirements in accordance with Vietnam's regulations. Our ferrotungsten factory is located in the Tan Lien Industrial Zone, Vĩnh Bảo District, Haiphong. Haiphong is the major port city in north-eastern Vietnam with a population of approx. 2.1 million.

Discover more about ferrotungsten's remarkable properties through our informative resources and articles.

Learn More About Our Ferrotungsten Factory

Explore our ferrotungsten plant and operations based in Vietnam.

Uses of Ferrotungsten

High-Speed

Tungsten is added to high-speed steels, to improve their mechanical properties and performance. Ferrotungsten enhances high-speed steel properties such as; hardness, wear resistance, and high-temperature strength. This makes them ideal for cutting tools and tough, high-resistance applications.

High Melting Point

Tungsten’s thermal conductivity helps maintain steel’s strength at high operating temperatures. The addition of tungsten also increases the steel’s red hardness. This means it retains its hardness even when heated to high temperatures. Overall, ferrotungsten plays a vital role in the mechanical properties of steel. This makes them suited for demanding applications.

High-Speed Steels

Tool Steels

Defence Steels

Super Alloys

Other Uses

Ferrotungsten FAQs

-

Ferrotungsten improves steel hardness, wear resistance, and strength at high temperatures. Ferrotungsten is essential in high-speed steels are used in cutting tools, drills, saw blades, punches and dies.

-

Ferrotungsten ( 78% W ) has a metallic steel grey lustre and a very high density (14 – 15.5 g/cm3). Ferrotungsten has a very high melting temperature (2400 to 2800 deg C) and a fine-grained structure of Fe₂W and Fe₇W₆.

-

Tungsten is a critical metal renowned for its robustness and highest melting point of all elements. Ferrotungsten is a tungsten and iron alloy containing 75 – 82% Tungsten with the rest as iron.

-

Ferrotungsten can be made using two processes. These are a carbothermic reduction in an Electric Arc Furnace or aluminothermic reduction under a metal cover. Ferrotungsten produced using an EAF produces the higher quality ferrotungsten.

We produce ferrotungsten mainly from tungsten mineral ores. Tungsten concentrates are smelted in our Electric Arc furnace. Tungsten impurities transfer into a glass-like slag that's poured out of the furnace. The heavier ferrotungsten is then removed by digging the semi-molten alloy out of the furnace in small quantities.

-

An Electric Arc Furnace melts material by pulsing an electric arc from electrodes into the material below. The charge is heated both by the electric current passing through the charge and by radiant heat. The electric arc temperature reaches around 3,000 °C (5,400 °F).

-

Ferro-tungsten is incorporated into steels to enhance their mechanical characteristics and overall performance. The inclusion of tungsten boosts the hardness, wear resistance, and high temperature strength of steel. The incorporation of tungsten also elevates the red hardness of the steel. This allows it to retain its hardness even when exposed to high temperatures. This renders these alloys highly suitable for demanding applications requiring superior wear resistance.

-

Ferrotungsten makes steel stronger at higher temperatures due to it's high melting point. This is in part, caused by the thermal conductivity of this tungsten.

-

Ferrotungsten is predominately produced in China, Russia, and at our Vietnamese facility. Minor quantities are also produced using aluminothermic reduction in Russia, and South America.

-

Ferrotungsten is produced from tungsten mineral concentrates, typically wolframite and scheelite ore. However tungsten scrap metal is also utilised in the process. Other raw materials used in the process are ferroSilicon, scrap steel, and pitch coke.

-

Our feedstocks comes from both tungsten mineral concentrate and select tungsten scrap. The mineral concentrates are sourced from countries that can show proof of origin and are not under any sanctions. These include those imposed by the UN, EU, OECD and other countries or regulatory bodies. Tungsten Metals Group Ltd. is a member of the Responsible Mining Initiative and is audited regularly to ensure compliance with all requirements.

-

No, Tungsten Metals Group Ltd, does not have a mine. We are involved in the downstream processing of tungsten.

-

Tungsten scraps that meet our quality requirements are added directly to the furnace as part of a blend of feed materials.

-

Our ferrotungsten is produced using our state-of-the-art Electric Arc Furnace.

-

We are capable of producing 4,000 tpa of Ferrotungsten at current capacity.

-

There are only 3 countries that manufacture Ferrotungsten to a high standard. China, Russia and in Vietnam - where we are located. Our production is valuable because we provide an alternative stable source of supply to China and Russia. We are also the largest production factory outside of these regions.