Tungsten Scrap Metal Recycling - When Economic Viability and Environmental Stewardship Intersect

Tungsten, a high-density critical mineral recognised for its outstanding hardness and durability, is not only a valuable resource but also a source of attractive returns, lower-cost production feedstock and enhanced environmental stewardship through tungsten scrap metal recycling.

Tungsten Scrap Metal: A Green Revolution

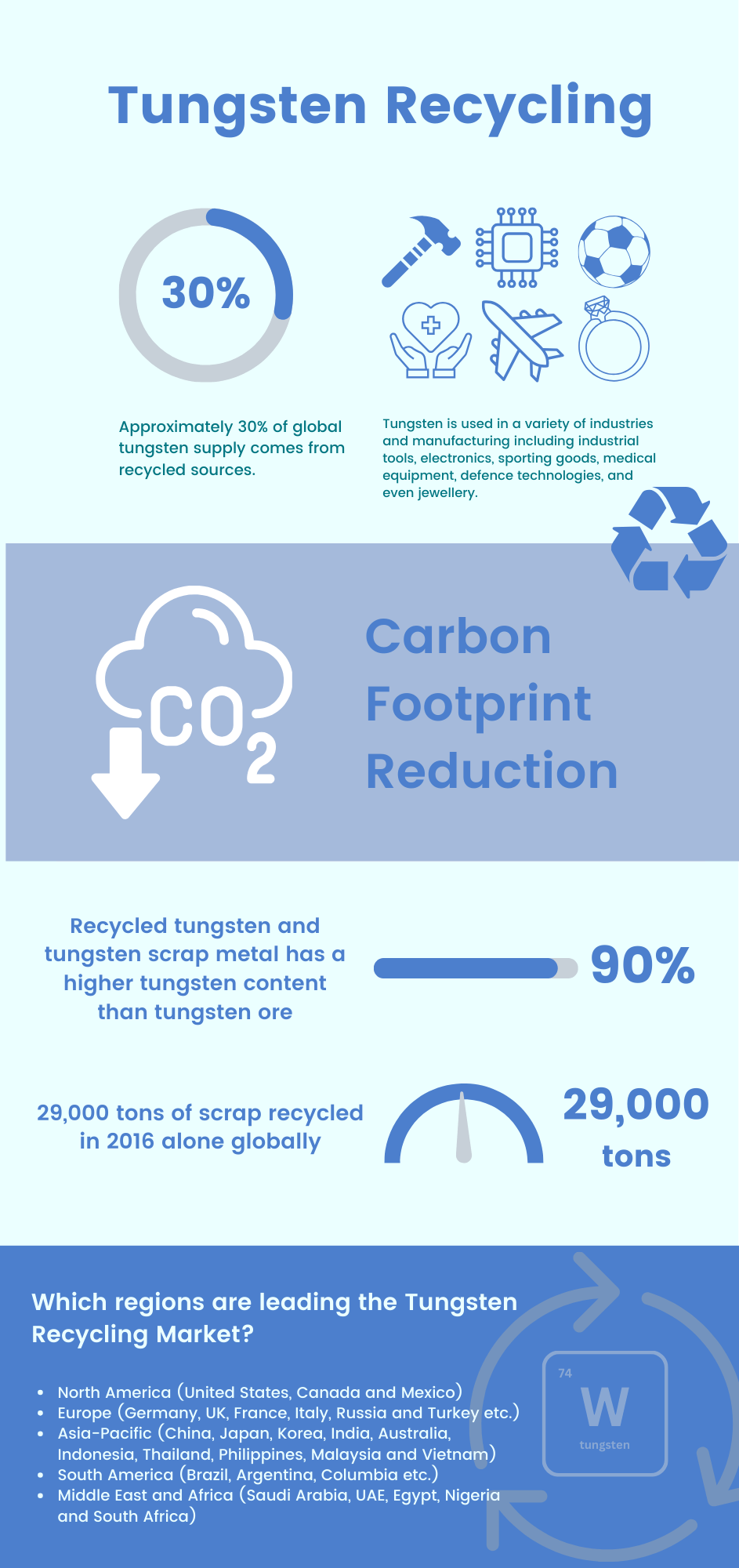

Tungsten recycling is more than just salvaging discarded materials; it is a critical step towards a greener planet. Industries utilising tungsten in their production are able to further eliminate the need for excessive mining, which can be an environmentally damaging operation, by recycling tungsten. Tungsten, which is commonly used in industrial tools, electronics, sporting goods, defence technologies, and even jewellery, may be repurposed to make new items, further reducing waste and carbon footprint.

An Economic Goldmine: Tungsten Recycling

Did you know that recycling tungsten is not only good for the environment but also good for your companies' wallets? Global tungsten consumption is increasing, and with approximately 30% of global tungsten supply coming from recycled sources, there is a sizable market waiting to be exploited. In fact, the global tungsten recycling market is projected to witness substantial growth in the coming years, presenting a lucrative opportunity for businesses and key sectors globally.

Recycled tungsten carbide and tungsten scrap metal has a higher tungsten content than tungsten ore

Frequently Asked Questions About Tungsten Scrap Metal Recycling

Why is tungsten recycling important?

Tungsten is a limited resource, and recycling contributes to its preservation for future generations. Furthermore, recycling lessens the environmental impact of mining, cutting carbon emissions and reducing production costs.

How is tungsten recycled?

Tungsten recycling is the process of collecting tungsten scrap metal from a wide range of source materials, treating them to eliminate impurities, and then melting the refined tungsten to make new goods.

Where can you find tungsten scrap metal?

Tungsten scrap metal can be discovered in a variety of areas, such as discarded electronics, industrial instruments, and even used lightbulbs.

Environmental Impact: Carbon Footprint Reduction

The production of tungsten from raw materials can be highly energy-intensive. By recycling tungsten, producers are able to dramatically reduce the amount of energy required, resulting in a significant reduction in carbon emissions. This method is consistent with global efforts to prevent climate change and encourages a circular economy.

Tungsten Recycling: A Win-Win Situation for Companies

Businesses, especially those in manufacturing and technology, stand to gain immensely from embracing manufacturers that are now incorporating tungsten recycling into their manufacturing processes. It not only aligns with corporate social responsibility aims but also provides a cost-effective alternative to procuring raw tungsten, resulting in a healthier bottom line.

Sustainability Embraced by Tungsten Manufacturers: A Paradigm Shift

Tungsten manufacturers are increasingly turning to tungsten waste metal as a potential alternative to ore-based feedstocks in a ground-breaking drive toward sustainability. Recognising the environmental and economic advantages, some manufacturers are now integrating recycled tungsten into their production processes. This transition not only lessens the industry's reliance on traditional mining but also establishes a precedent for responsible resource management. As the demand for environmentally friendly practices grows, the use of tungsten scrap metal as a principal feedstock represents a significant step forward in altering the tungsten production landscape. This not only coincides with global sustainability goals but also positions these manufacturers as responsible and forward-thinking corporate leaders.

This strategic shift in the manufacturing environment represents a commitment to circular economies, highlighting the value of closed-loop systems in which materials are continuously recycled and utilised. Tungsten manufacturers who use recycled feedstocks not only reduce their environmental impact, but also reap a number of economic benefits from this sustainable approach.

The use of tungsten waste metal in manufacturing operations has several advantages. For starters, it reduces the environmental impact of traditional mining, which is known for habitat disturbance and resource depletion. This transition also tackles concerns about mining operations' often hazardous conditions, promoting safer and more ethical industrial practices.

Furthermore, the financial incentives are enormous. Manufacturers who use recycled tungsten feedstocks benefit from a more secure supply chain, less reliance on fluctuating raw material prices, and, most crucially, a boost in brand image. As consumers place a greater emphasis on ecological and ethical practices, businesses that use tungsten scrap metal as a feedstock enjoy a competitive advantage, generating goodwill among environmentally sensitive customers.

The ripple effect extends beyond individual enterprises, causing entire industries to reassess their material sourcing policies. This move highlights the transformative impact of sustainable practices, suggesting a collective commitment to reducing the environmental footprint of tungsten production.

As the use of tungsten scrap metal gathers pace, the manufacturing sector finds itself at a crossroads of innovation and accountability. This paradigm shift is more than a passing fad; it is a long-term commitment to restructuring the industry in accordance with global environmental aspirations. The use of tungsten recycling in production processes is a watershed moment in which economic viability and environmental care now intersect.

Ultimately, the journey of tungsten scrap metal recycling is a pathway to both environmental stewardship and financial prosperity. It's time to turn waste into profit and for industries around the globe to adopt a larger role in a movement that improves our world.